Why is molecular sieve used as an adsorbent for dehydration?

Ⅰ. Structure and properties of molecular sieves

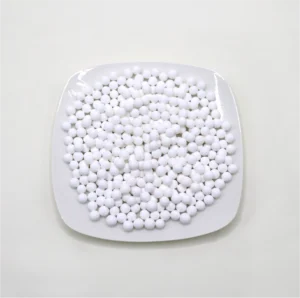

Molecular sieves are porous materials with regular pore structures. Due to their high specific surface area and strong adsorption capacity, they are widely used in fields such as chemical engineering, medicine, and environmental protection. The pore size of molecular sieve materials can be designed and adjusted according to the requirements of different applications.

Ⅱ. Adsorption principle of molecular sieves in dehydration process

In industrial production, the presence of moisture is highly detrimental to many chemical reaction processes, thus requiring dehydration treatment. During the dehydration process, the main function of molecular sieves as adsorbents is to adsorb and remove water molecules. The adsorption capacity of molecular sieves is based on their pore size and chemical reaction characteristics, enabling them to efficiently adsorb water molecules. After adsorbing water molecules, molecular sieves can release the adsorbed water molecules through heat and/or vacuum, achieving periodic regeneration. Currently, the main deep dehydration equipment for natural gas in both domestic and international markets utilize synthetic zeolite molecular sieves, utilizing their strong adsorption effect on water vapor molecules in gases to achieve the goal of deep dehydration. Synthetic zeolite molecular sieves are a type of aluminum-silicate crystal with a strict framework structure, whose internal framework is composed of silicon-aluminum tetrahedra and has numerous three-dimensional connected micropores. As a strong polar adsorbent, it has uniform pore size and high selective adsorption separation ability. With the increase in the silicon-aluminum ratio, the polarity of the molecular sieve gradually decreases, so molecular sieves with a low silicon-aluminum ratio have stronger water absorption capacity and are more suitable for deep gas dehydration.

III. Advantages of using molecular sieves as dehydration adsorbents

1. High adsorption capacity. Molecular sieves have a high specific surface area and regular pore structure, and thus have extremely high adsorption capacity, capable of quickly and efficiently adsorbing water molecules.

2. High regenerability. The highly regular pore structure of molecular sieve materials enables periodic regeneration, extending service life and reducing costs.

3. Adaptability to different dehydration requirements. The pore size of molecular sieves can be designed and adjusted according to different application requirements, adapting to various dehydration treatment requirements.

4. Molecular sieves can effectively dry gases at higher temperatures.

5. Molecular sieves have the ability to selectively adsorb water, avoiding the failure of the adsorbent caused by the co-adsorption of heavy hydrocarbons.

6. Molecular sieves are not easily damaged by liquid water, while silica gel and other adsorbents will rupture in water.

7. Molecular sieves can achieve deep gas dehydration, and under normal circumstances, their adsorption capacity is higher than that of other adsorbents, thereby reducing the size of the drying tower and saving costs.

When gas passes through the molecular sieve bed, water vapor molecules in the gas flow into the pores inside the molecular sieve. Since water molecules are polar strong molecules, they are adsorbed on the pores and no longer flow with the gas; while hydrocarbon gases like methane belong to non-polar molecules and can pass through smoothly, thus allowing the gas to be dried. As the amount of water molecules adsorbed by the molecular sieve in the adsorption tower increases, its adsorption capacity gradually decreases. When a certain value is reached, the water molecules in the gas exiting the adsorption tower will exceed the specified value, indicating that the molecular sieve has been saturated with adsorption. At this point, the molecular sieve in the adsorption tower must be regenerated. The regeneration process is the process of removing the water adsorbed in the micro-pores of the molecular sieve and reactivating the molecular sieve. The reasonable design of the regeneration process is crucial for the continuous operation of the dryer. As the filler tower for molecular sieve adsorbing moisture, regardless of the design chosen, the molecular sieve will eventually become saturated and lose its ability to adsorb moisture. Therefore, choosing a reasonable regeneration process and parameters becomes the focus of dryer design. A reasonable regeneration process can achieve effective regeneration with as low consumption (electric heating power, gas loss rate) as possible.

In conclusion, molecular sieves, due to their high adsorption capacity and high regenerability, are very suitable as dehydration adsorbents and are widely used in industrial production.