How to deal with the problem of water entering the molecular sieve in a pressure swing adsorption nitrogen generator?

When water enters the molecular sieve of a nitrogen generator, its adsorption capacity will be affected, resulting in a decrease in nitrogen purity and insufficient flow. To restore the adsorption capacity of the molecular sieve, the drying method can be adopted for treatment. During drying, it is necessary to ensure the appropriateness of the drying temperature and time.

Generally, the drying temperature should be controlled between 80 and 100 ℃, and the drying time should be no less than 4 hours. This can effectively remove the moisture in the molecular sieve and restore its adsorption performance.

However, merely conducting drying treatment may not be sufficient to completely solve the problem. If there are issues with the purification system in front of the nitrogen generator, such as poor water removal effect of the compressed air dryer or failure to replace the filter core of the pipeline filter in time, even if the molecular sieve is dried, water may still enter the nitrogen generator. Therefore, when dealing with the problem of water entering the molecular sieve of a nitrogen generator, it is also necessary to inspect and repair the compressed air treatment system in front of it to ensure its effective removal of moisture.

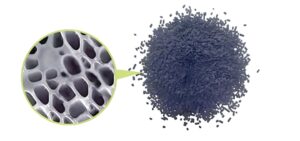

In addition, if the water ingress into the molecular sieve is severe or the molecular sieve has been “poisoned and failed”, it may be necessary to replace the molecular sieve. When replacing the molecular sieve, reliable quality products should be selected and the correct installation and usage methods should be followed.

In conclusion, after water enters the molecular sieve of a nitrogen generator, drying treatment can be carried out, but it is necessary to combine the maintenance of the purification system in front and the replacement of the molecular sieve to comprehensively solve the problem. To prevent water from entering the nitrogen generator, regular inspection and maintenance of the air purification and drainage work of the nitrogen generator should be carried out, including air tank drainage, refrigeration effect of the cold dryer, and drainage of the pre-filter. All filter consumables should be replaced regularly to ensure the normal operation of the nitrogen generator and the stability of nitrogen quality. In addition, the nitrogen generator itself does not require frequent maintenance and care, but the air purification and drainage work is crucial.