How to extend the Service Life of Carbon Molecular Sieves?

When discussing the service life of carbon molecular sieves, several key factors must be mentioned, which are directly related to their long-term performance and maintenance strategies.

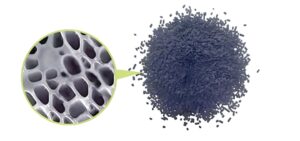

一:The quality of raw materials and the precision of the production process are the keys to laying a foundation for a long service life. The selection of high-quality raw materials can ensure that the molecular sieves maintain stable physical and chemical properties in complex and changeable working environments, while advanced production processes can precisely control the pore structure, making them more efficient in adsorbing target molecules and reducing unnecessary wear.

二: The operating environment has a significant impact on the lifespan of carbon molecular sieves: harsh conditions such as high temperatures, high pressures, and corrosive gases can accelerate the aging process of the molecular sieves. Excessively high inlet temperatures can increase the desorption rate of carbon molecular sieves, while excessively high inlet pressures can increase the adsorption capacity, thereby causing greater wear and tear. Therefore, proper design of operating conditions and regular maintenance are crucial. Optimizing the operation process, controlling the operating temperature and pressure within the recommended range, and adopting appropriate pretreatment measures to reduce the direct impact of harmful substances can effectively extend their service life.

三: Control gas flow: Excessive gas flow in the nitrogen generator can accelerate the aging of carbon molecular sieves. Therefore, it is necessary to control the gas flow as much as possible during use to reduce damage to the carbon molecular sieves.

四: Reasonable usage: Avoid frequent on/off cycles and maintain a long-term running state every day. This helps stabilize the gas flow and pressure, reducing damage to the carbon molecular sieves.

五: Regeneration treatment is an important means to extend the lifespan of carbon molecular sieves. Regular and correct regeneration operations can restore the adsorption capacity of the molecular sieves and remove impurities accumulated due to saturation, thus maintaining their efficient operation. This includes selecting appropriate regeneration temperatures, times, and regeneration gases to ensure a thorough regeneration process without damaging the molecular sieve structure.

六: Maintenance and repair of carbon molecular sieves in nitrogen generators

During operation, carbon molecular sieves may encounter various problems such as contamination and aging. To ensure the normal operation of the nitrogen generator, timely maintenance and repair work are necessary.

1. Clean the carbon molecular sieves: Regular cleaning of the carbon molecular sieves is essential to maintain their normal working condition. Common cleaning methods include water rinsing or ultrasonic cleaning.

2. Replace the carbon molecular sieves: When the lifespan of the carbon molecular sieves expires, they should be replaced promptly to avoid affecting the normal operation of the nitrogen generator.

3. Inspect the carbon molecular sieves: Avoid ineffective use of the carbon molecular sieves.

It is worth noting that carbon molecular sieves are one of the more expensive components in nitrogen generators. Therefore, during maintenance and repair, extreme care should be taken to avoid causing secondary damage to the carbon molecular sieves.

With technological advancements, new materials and modification methods are constantly emerging, providing new possibilities for extending the lifespan of carbon molecular sieves. For example, enhancing the wear resistance and corrosion resistance of molecular sieves through surface modification, or developing composite materials with higher stability, are current research hotspots. These innovations not only have the potential to extend the lifespan of molecular sieves but also further enhance their performance in various applications.

Conclusion:With proper usage and maintenance, the lifespan of carbon molecular sieves can be maintained for about three years. It is important to strictly follow the product manual during the operation of the nitrogen generator. Proper maintenance and correct usage methods can significantly extend the lifespan of the carbon molecular sieves in the nitrogen generator. Improper use or lack of regular maintenance may cause damage or severe aging of the carbon molecular sieves, thereby affecting the purity and output of nitrogen. The lifespan of carbon molecular sieves is a result of a comprehensive consideration of factors such as raw materials, processes, environment, maintenance, and technological progress. By continuously optimizing these factors, we can achieve a longer and more efficient service cycle for carbon molecular sieves.