How to load activated alumina and molecular sieves correctly?

一、Loading sequence of activated alumina and molecular sieves

The loading sequence of alumina and molecular sieves should be to load the bottom layer of the reactor first and then load layer by layer upwards.

1. Working principle of alumina and molecular sieves

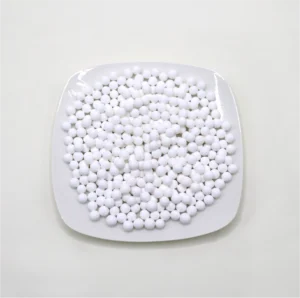

Alumina and molecular sieves are highly efficient separation materials. Their main function is to fix impurities, certain molecules or ions in the sieve through the pores in the sieve, thereby achieving separation. The pore size of alumina and molecular sieves determines the size and type of substances they can separate.

2. Loading sequence and reasons of alumina and molecular sieves

During the loading process of alumina and molecular sieves, they should be loaded layer by layer from the bottom to the top. The reasons are as follows:

A. Avoiding sieve particles falling into the reactor

If loading starts from the top layer, the sieve particles will fall from a height. For deep reactors, when the particles fall from the top, they will cause a large number of particle impacts inside the reactor, which will lead to many particle fractures and the generation of fine particles. These particles will flow to other devices with the gas or liquid, affecting the stability of the entire system.

B. Improving reaction efficiency

When loading alumina and molecular sieves in the order of bottom, middle, and top layers, the pore size of the sieve can be fully utilized to improve reaction efficiency. The different pore sizes of alumina and molecular sieves determine the relative affinity and separation efficiency of different molecular sizes in the sieve.

3. Summary

The loading sequence of alumina and molecular sieves should be to load the bottom layer of the reactor first and then load layer by layer upwards. This can avoid particles falling into the reactor, improve reaction efficiency, and make the entire system more stable.

二、What is the loading sequence of alumina and molecular sieves?

When loading a fixed-bed reactor, alumina should be loaded first and then molecular sieves. This can effectively improve the efficiency of the reactor.

1. Why load alumina and molecular sieves?

In a fixed-bed reactor, alumina and molecular sieves, as fillers, can improve the efficiency of the reactor. Alumina can withstand high temperatures and gas flow impacts, preventing damage to the reactor; while molecular sieves have the function of selectively adsorbing molecules, which can improve the selectivity of the reaction and the purity of the product.

2.What is the loading sequence of alumina and molecular sieves?

When loading a fixed-bed reactor, alumina should be loaded first and then molecular sieves. The reasons are as follows:

1. Protecting molecular sieves: Before loading molecular sieves, alumina should be filled into the reactor first to avoid direct impact of gas flow on the molecular sieves, thereby protecting the molecular sieves from damage.

2. Improving reaction efficiency: Under the protection of alumina, the loaded molecular sieves can better perform the function of selectively adsorbing molecules, thereby improving the selectivity of the reaction and the purity of the product.

3. Saving fillers: Filling alumina in the reactor can play a role in the initial dispersion of the fillers, thereby reducing the amount of fillers used when filling molecular sieves and saving costs.

三、 Precautions for filling alumina and molecular sieves?

1. Size of fillers: When filling alumina and molecular sieves, the appropriate size of fillers should be selected according to the size and requirements of the reactor to fully utilize the space of the reactor.

2. Loading sequence: Alumina should be filled into the reactor first, and then molecular sieves should be gradually filled to the top of the reactor. Be careful not to mix alumina and molecular sieves.

3. Tamping filling: The fillers should be filled using the tamping method. During the filling process, the reactor should be vibrated in time to ensure that the fillers are fully dispersed, reducing voids, and improving reaction efficiency.

Conclusion

When filling a fixed-bed reactor, alumina should be filled first and then molecular sieves. This can improve the efficiency of the reactor and the purity of the product. When filling with alumina and molecular sieves, attention should be paid to the selection and size of the fillers, and the method of vibration compaction should be used for filling.